Complex aerospace components that once took months to manufacture are now printed in days. Major aerospace companies like GE Aviation and Airbus have revolutionized production through additive manufacturing, achieving 50% weight reductions while exceeding performance standards. This transformation represents the industry's shift to mission-critical 3D printing capabilities.

Aerospace 3D Printing: Additive Manufacturing

Aerospace 3D Printing: Additive Manufacturing

Instructors: Lluis Foreman

Access provided by ExxonMobil

Recommended experience

What you'll learn

Apply principles and benefits of additive manufacturing to check compatibility for new aerospace components.

Select appropriate materials and processes to fabricate aerospace-grade 3D printed parts that meet stringent regulatory and structural requirements.

Apply design guidelines and analyze case studies for additive manufacturing in aerospace industry.

Skills you'll gain

- Process Analysis

- Mechanical Design

- Equipment Design

- Sustainable Design

- Failure Mode And Effects Analysis

- Design Strategies

- Sustainable Engineering

- Process Development

- Materials science

- Engineering Design Process

- Process Control

- Manufacturing Processes

- Mechanical Engineering

- Finite Element Methods

- Process Engineering

- Engineering

- Design Specifications

- Process Validation

- Aerospace Basic Quality System Standards

- 3D Assets

- Skills section collapsed. Showing 9 of 20 skills.

Details to know

Add to your LinkedIn profile

1 assignment

February 2026

See how employees at top companies are mastering in-demand skills

There are 3 modules in this course

The module addresses engineering challenges, such as scalability and quality control, offering tailored solutions for aerospace applications. It evaluates the suitability of aerospace components for AM based on complexity and performance requirements. Additionally, it examines recent trends in AM within the aerospace and automotive industries, emphasizing its role in achieving sustainable development goals through resource-efficient and lightweight designs.

What's included

4 videos2 readings1 peer review

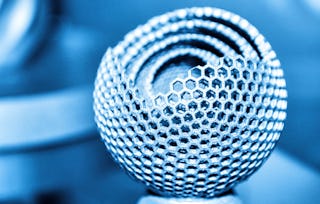

This module investigates the selection and optimization of materials and processes for aerospace additive manufacturing, prioritizing performance-driven material properties. It defines engineering criteria for material compatibility, including strength, thermal resistance, and printability, essential for aerospace demands. The module reviews the use of metals in aerospace AM, highlighting their reliability under extreme conditions. It explores advanced materials specifically developed for AM to enhance component durability and functionality. Process optimization techniques, such as parameter tuning and post-processing, are detailed to improve print quality and performance. The module also analyzes trade-offs between cost, performance, and production speed in material and process selection for aerospace AM.

What's included

3 videos2 readings1 peer review

This module presents practical design strategies for leveraging additive manufacturing to optimize aerospace components. It introduces methods to exploit AM’s capabilities for creating complex, high-performance parts. Advanced topology optimization techniques are explored to reduce weight while maintaining structural integrity. The module discusses selective laser melting (SLM) for producing lightweight, high-strength components through precise material fusion. It introduces tools for automating topology optimization in aerospace design and outlines practical steps for implementing optimized AM designs from concept to production. The suitability of AM for specific aerospace components is evaluated, considering material properties, manufacturing processes, and optimized designs. A concluding video summarizes key learnings and applications of AM in aerospace component design.

What's included

4 videos2 readings1 assignment2 peer reviews

Offered by

Why people choose Coursera for their career

Felipe M.

Jennifer J.

Larry W.

Chaitanya A.

Explore more from Physical Science and Engineering

Indian Institute of Technology Guwahati

University of Michigan

Arizona State University

Arizona State University