Designing a product is only part of the process. Now, can that product be manufactured? A CNC machinist works with computer numeric controlled (CNC) machines from generating the machine code to machine setup and run. Understanding both CAD and CAM is essential to this portion of a design. Even if you are not the end user who programs a machine, it is invaluable to know how it’s done. This knowledge translates directly to part design by helping make intelligent design decisions with manufacturing in mind. This course introduces you to the integrated CAD/CAM approach behind Fusion 360 CAD/CAM as well as 3D printed design setup and finally assembly and testing. All stages of product design in one place!

Manufacturing Process with Autodesk Fusion 360

This course is part of CAD and Digital Manufacturing Specialization

Taught in English

Some content may not be translated

Instructor: Autodesk

20,530 already enrolled

Included with

Course

(483 reviews)

97%

Details to know

Add to your LinkedIn profile

6 quizzes

Course

(483 reviews)

97%

See how employees at top companies are mastering in-demand skills

Build your subject-matter expertise

- Learn new concepts from industry experts

- Gain a foundational understanding of a subject or tool

- Develop job-relevant skills with hands-on projects

- Earn a shareable career certificate

Earn a career certificate

Add this credential to your LinkedIn profile, resume, or CV

Share it on social media and in your performance review

There are 4 modules in this course

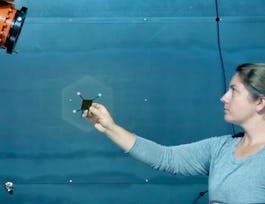

Most retail production quad and multirotor chassis are made of flat plates of carbon fiber or injection molded plastic. Flat plates of composite materials are often cut on a machine that uses high pressure water and abrasives. This allows you to cut almost any material without introducing heat, which could affect its structure and properties. In this week's lessons, we'll explore how to setup and validate a 2D waterjet cut on a quadcopter chassis.

What's included

21 videos7 readings2 quizzes2 discussion prompts

Autodesk® Fusion 360™ is capable of much more complex CNC programs beyond a 2D cut. We explore some of the advanced functionality by creating toolpaths on a propeller to explore multi-axis machining.

What's included

17 videos5 readings1 quiz1 discussion prompt

You finally have a complete design and all the parts in hand, now what? This stage of the process can be a rather large task the first time through. From complex wiring, cable management, and overall assembly, we will step through the process. Even if you aren’t designing and building your own quadcopter, this is great information to have for when you do.

What's included

15 videos5 readings1 quiz1 discussion prompt

What's included

7 videos8 readings2 quizzes1 peer review1 discussion prompt

Recommended if you're interested in Mechanical Engineering

Why people choose Coursera for their career

Learner reviews

Showing 3 of 483

483 reviews

- 5 stars

78.30%

- 4 stars

16.11%

- 3 stars

3.30%

- 2 stars

0.82%

- 1 star

1.44%

Open new doors with Coursera Plus

Unlimited access to 7,000+ world-class courses, hands-on projects, and job-ready certificate programs - all included in your subscription

Advance your career with an online degree

Earn a degree from world-class universities - 100% online

Join over 3,400 global companies that choose Coursera for Business

Upskill your employees to excel in the digital economy

Frequently asked questions

Yes! Autodesk also has Learning Pathways to start you on your learning journey, including certification prep courses and practice tests—so you feel confident when you take an Autodesk certification exam.

Visit this page to learn how to download Fusion 360 and to learn about the Autodesk Education license terms.

http://www.autodesk.com/products/fusion-360/students-teachers-educators?mktvar002=702476&utm_medium=affiliate&utm_source=other&utm_campaign=amer-edu-aex-fy18-fusion-360-acquisition&utm_id=702476&rid=

Fusion 360 is available for free to all users as a 30-day trial version. A free, 1-year startup license is also available for hobbyists, enthusiasts, makers, and emerging businesses that make less than $100k in revenue per year. After one year, you can reselect the startup entitlement or transition to a commercial entitlement.

Professionals earning more than $100k annually can purchase a Fusion 360 subscription as an annual or monthly license. For more information, visit the Fusion 360 subscribe page: https://www.autodesk.com/products/fusion-360/subscribe?plc=F360B&term=1-YEAR&support=ADVANCED&quantity=1